Популярные статьи

|

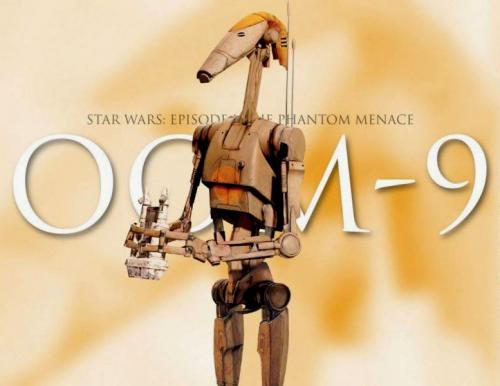

Droid Officer OOM-9

This idea fell to my head last year when I was speculating on the project about Star Wars for Microsoft company… The idea couldn't be put into practice within that project but I kept it in my head. As you could have realized by the picture, this is a robot from "Star Wars" movie. Droid Officer OOM-9. There were also Corporals, soldiers, pilots and many other kinds of Droids but I fixed on the officer. Leaping ahead I’d like to say that it was the most expensive, time-consuming and complex modding project in my life.

The work was started with creation of hands of the robot. At once I want to make a reservation: since robot is anthropomorphic I'll use in my description names of body parts. So, let's begin. Don't be surprised with fanciful shapes of workpieces.! Robot production took a lot of metal and all kinds of cutting waste were used. At first I mark up an aluminum plate of 20 mm in thickness.   Then I drill the outline and cut it out with a fretsaw. This is a typical method for cutting plates by outline.    The prospective joints are formed on the roll-over table.   I make a cylinder-shaped swivel block on the reverse side.   Shoulder joint is made from a plate. At the same time the cylinder-shaped swivel block is created.   Shoulder block rotation is performed in such a way.      Then I imitate mechanic muscles. They are made of aluminum pipes. The muscles are fixed to the shoulder joint with a cone hinge.  The pin is locked with a screw nut on the inside what helps to avoid inadvertent unscrewing.    The rest of the day was spent on cutting the huge aluminum bar to smaller parts. This bar lay about and it had diameter of 300 millimeters.     When cutting was finished I circularized the part in the turning machine.       I decided to readjust it and moved support as high as possible. This moves rotation center and reduces swivel radius. For that purpose I had to readjust and reface the ball socket several times.     Now it’s time for the elbow joint.   I continue parting aluminum bars. I need two bars to produce hands. The bars are cut out from a big rectangular workpiece.  This picture shows intermediate variant of a future hand.     It also has a complex shape and is processed with a turning machine. All grooves and final shape are provided by means of milling.   |